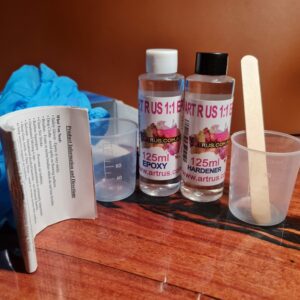

1KG kit 1:1 ART R US Epoxy Resin

$59.00

- Description

- Additional information

Description

1:1 Coating and Casting Epoxy Resin – ART R US

Ultra clear epoxy resin is designed for coating wood table tops, bar tops, countertops, floors, and artwork This also can be used for casting crystal clear coasters and trays, jewellery, crafts, resin art, and models. can cast up to 3cm | Self-levelling | UV Resistant | Virtually Odorless | FDA Compliant | Crystal Clear | Easy 1:1 Mix Ratio 50:50 mixing by Weight

CLEAR GLASS EPOXY RESIN Top Coating Features:

- Self-Levelling

- UV Resistant

- High Gloss

- Excellent Air Release

- Excellent Color Stability

- Improved Surface Appearance

- Water Resistant Coating

- Blush Resistant

- Eliminates Craters, Crawling and Fish Eyes

- Improved Impact Strength

Coverage is approximately 300 ml per square meter per coat in winter and up to 1L per square meter in summer.

Mixing Ration: A: B = 1:1 Operation time 60 minutes

Curing time: 6-8 hours At room temperature 24-30c in cold weather it will take longer to cure 24 hours to fully cure

INSTRUCTIONS

1. Determine how much epoxy resin you’ll need

2. Accurately measure both resin and hardener

3. Mix thoroughly for 3 minutes, scraping the sides and bottom as you stir (mix longer for larger quantities) (Start pouring or applying the epoxy immediately, the larger the quantity of mixed material in the cup the faster the Pot-life and working time)

4. you can colour your Epoxy resin by Adding ( mica powder, glow-in-the-dark, Neon powder, Chameleon powder, Dye, Alcohol ink, and Acrylic paint)

Be aware that warming your epoxy resin shortens the working time by approximately 10 minutes.

Wait 3 days for a full cure and 30 days for a full hard cure.

AVOID THE FOLLOWING WITH EPOXY RESIN CURE

Don’t add more hardener to the mixture thinking this will increase cure time – it won’t. It will simply throw off the delicate 1:1 mixing ratio, causing your resin to not cure at all and remain sticky indefinitely.

Don’t replace the hardener with another brand of hardener that advertises a quicker cure time.

Don’t add any extra agents to the mixture to promote a quicker cure.

- Mica Powder Ratio in Epoxy resin

you can add mica powder or any other pigment between 2% to 10% max Why is my epoxy not hardening?

Additional information

| Weight | 1000 g |

|---|---|

| Dimensions | 23 × 15 × 9 cm |